In cooperation with n’H, neue Holzbau AG from Lungern, the Membrane Construction division of HP Gasser AG will build a wooden membrane roofing (HPG Memcover®) for Paul Gisler AG in Cham to cover the storage area. The project is already completely planned and the first works are in preparation. The final assembly will probably be completed in June 2020 after a construction period of only three weeks.

When customers become contractors

For many years now, Paul Gisler AG and HP Gasser AG have been in a firm relationship with each other. As a specialized plumbing company, Paul Gisler AG is also very active in the flat roof sector. Thus, an intensive cooperation developed quite soon, for example when it came to flat roof elements from HP Gasser AG.

The successful and always very enriching cooperation has now led to the fact that we were commissioned by Paul Gisler AG to design and ultimately implement a roofing for the storage area of the plumbing shop. For this purpose, our Membrane Construction division not only has the appropriate capacities, but also the correspondingly high level of experience.

So a customer for roof window elements became by a successful cooperation now also a contractor for membrane construction, whose desires and requirements we will fulfill only too gladly.

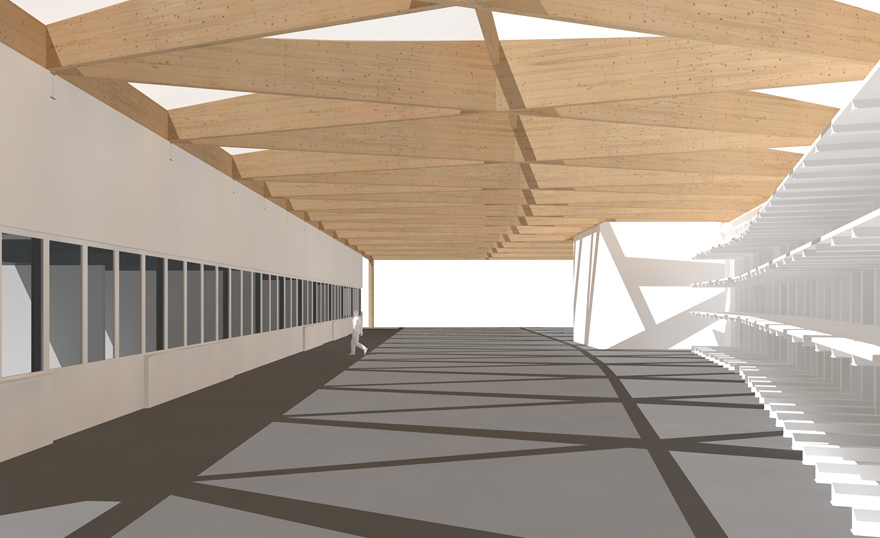

Wooden structure implements company logo

Individual solutions are increasingly in demand. Even if the planning fundamentals are based on standards, we are repeatedly asked how, for example, typical shapes or elements can be incorporated into such standards. In the special field of timber membrane construction, such customer requests and special solutions can be catered for. Every hall, every membrane roofing is unique and requires exact planning and preparation while taking into account the client’s ideas and wishes.

For Paul Gisler AG, a triangle is an essential part of the company logo. And it was precisely this triangle that the architect also stylistically incorporated into the planning and building of the HPG Memcover® for the storage yard. This can only succeed with special planning, which we have tackled together with “neue Holzbau AG” directly from our neighborhood.

In the end, the result is a construction that picks up the triangle from the company logo of Paul Gisler AG. The result is an individual solution that fits the commissioning company to a T and still takes into account the speciality of membrane construction.

Community plant will be built in June 2020

The final preparations are now underway for the construction of the special wooden membrane structure, which also includes existing buildings. This means that work on the wooden structure and the subsequent membrane covering must be carried out during ongoing operations at Paul Gisler AG.

While the “new Holzbau AG” is now equipping itself with material and assembly accessories, we are already in the prefabrication of the membrane covering. Then, in a few weeks, the starting signal will be given for the assembly and after only 21 days of assembly time, the impressive HPG Memcover® for the storage yard of Paul Gisler AG in Cham will be in place.

This is how we understand the service to the customer, which we implement with the appropriate partners and always a good portion of individuality. To the delight of the client and to our delight when clients become contractors.

Architect: Kollektiv Juma Architekten GmbH

Just in time for the start of 2020, it was as good as finished, the new production hall of HP Gasser AG in Lungern, Canton Obwalden. With the Kristall 2020 production hall, the family-run company for roof window element construction and membrane construction with its attached carpentry shop was able to significantly expand its production capacity and at the same time offer its employees a better working environment.

The industrial building is impressive not only because of its size, equipment and expanded capabilities for more effective production. It is above all the external facade facing the neighbors that attracts interest and attention. On the HPG Memfas® (membrane facade), which was specially prefabricated in the company’s own plant, neighbors and interested curious people have for some time been able to view what is probably the largest photo in the canton of Obwalden.

Integration into the environment guaranteed

A deliberate decision was made to use a motif that almost completely recreates the neighbors’ now obstructed view of Lake Lunger and the surrounding mountains. The large-format print motif directly on the membrane façade is the congruent image of what was previously visible with an unobstructed view. This is eye-catching, beautiful and integrates the new production hall of HP Gasser AG completely into its surroundings.

A photo facade that makes school

The unusual facade design has already caught the eye of many. Not only because of the visually outstanding effect, but also because of the membrane facade itself. It does not obstruct the view from the hall to the outside, but with its skilful photorealistic design it offers the uncompromising and harmonious integration of an industrial building into its immediate surroundings.

This is interesting from many points of view. Because HP Gasser AG’s customers also have a tangible example right here in front of their eyes of what is possible with modern printed membrane facades. It doesn’t just have to be logos or artistic objects that make the membrane façade a real eye-catcher. Even the previous view can be recreated, at least visually. Of course, this means that many other motifs are also conceivable, turning a seemingly simple membrane facade into a veritable gem for the eye.

Just as, for example, on the new production hall of HP Gasser AG, the former view of the lake and mountains remains visible, of course under the bright blue sky of Switzerland.

What is feasible is what is conceivable

For all those who are interested in the membrane facades of HP Gasser AG, this also opens up new possibilities in the way of thinking about how a membrane facade can appear, especially on the outside. Whether photorealistic, futuristic, playful, detailed, advertising or simply in the appearance of the material, almost anything is possible.

You just have to dare to think beyond the boundaries of the known and the familiar for once and completely new possibilities arise. In conversation with the neighbors of HP Gasser AG, one thing quickly becomes clear: The new membrane façade on the Kristall 2020 production hall is a real eye-catcher and a skillful replacement for the obstructed view. Because now the hall fits perfectly into the landscape and even in gray weather the “view” of an enchantingly blue Lake Lunger with an equally blue sky is possible.

The first sunny days of spring have already shown that summer can be a great one again. Then the sun shines from the blue sky for hours on the roofs, in the gardens and on the terraces. Nice for real sun worshippers, but sometimes a little too much of a good thing. That’s where a comfortable heat shield does you good. HP Gasser AG has some practical solutions in its portfolio.

Modern roof windows can also be a heat shield

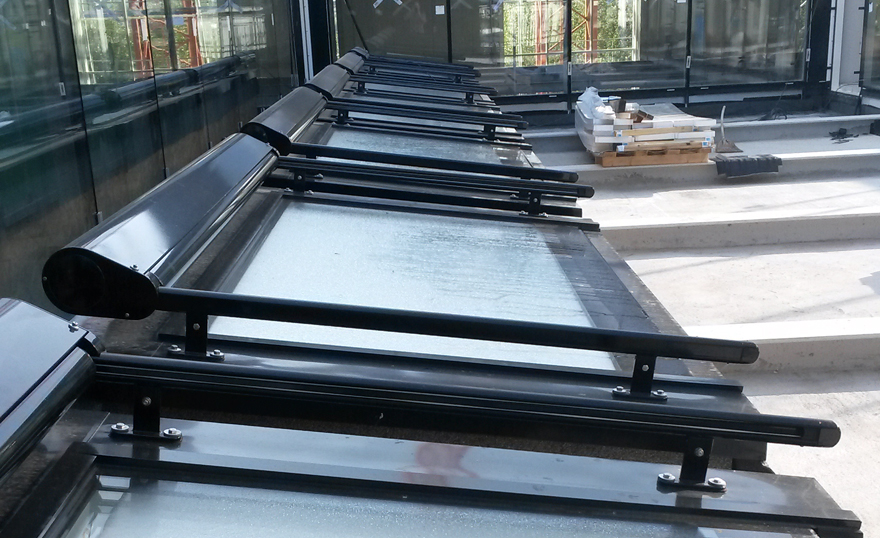

Especially under the roof it gets really hot and stuffy on sunny summer days. Even with ventilation options such as roof windows, it can be uncomfortable if the glazing of the roof windows does not meet the latest standards and there is no shade installed at the window.

Modern roof window elements not only have thermal insulation properties for cold days, they can also be a good heat shield in the summer. After all, a decent thermal insulation glazing not only keeps the heat inside the house in winter, but can also keep the heat outside in summer. In addition, blinds or sun blinds can be installed, which is not a big problem with modern roof window elements. Special coatings on the glass can also reduce excessive summer heating under the panes. There are thus good possibilities for installing sensible summer heat protection for life under the roof. Even without expensive and energy-consuming air conditioning. By the way, good insulation of the roof surfaces also contributes to heat protection in summer.

Sun sails for garden and terrace

But the technical details are also remarkable. For example, we use only high-quality insulating glass as triple stepped glass in the HPG oecoline quadro®. With a standard frame height of 500 millimeters, a full 200 millimeters of insulation are installed, resulting in an excellent U-value over the entire element of 0.35 W/m2K (for a ceiling opening of 1,000 x 1,000 mm). The interior cladding is usually created on site with a plasterboard.This allows the ceiling opening to be finished in the same material as the adjacent building components without the need for separation joints.

Even more protection from hot sun and the harmful UV rays can provide in the garden or on the terrace a sun sail. HP Gasser AG from Lungern/Obwalden also has attractive, robust and durable products for this in its range. The HPG Memsail® sun sails are elegant and durable shade providers that do a good job not only on hot summer days.

The strong fabrics and reliable bracing ensure that good shading is possible in the chosen place. In addition, the sun sails always set design highlights in the garden or on the terrace. And what could be nicer on a hot summer day than a shady spot under an HPG Memsail® sun sail in various sizes, designs and colors?

A few more tips

Also apart from the shady and cooling products from HP Gasser AG, we would like to provide you with a few long proven tips and tricks against too much summer heat. First and foremost, always drink enough! Especially non-alcoholic and unsweetened drinks are always good in warm weather. It is best to air the room thoroughly in the early morning when it is still cool. During the day, keep the windows closed as much as possible. That way, not too much summer heat from outside comes inside. Provide shaded window areas wherever possible. The shade in front of the window is always better than the shade behind the window. So shade from the outside so that the heat cannot accumulate behind the glass surfaces. In the evening, after sunset, ventilate the room properly and the indoor climate should be back to normal. Slightly moving air, for example from a fan, seems cooler to us than stagnant air. If you hang up in addition still a few light damp cloths in the area, these work by the evaporation coolness like an air conditioner.

Surely you know one or the other trick, but usually much of summer heat protection can already be solved well with modern windows and attractive shading systems. In any case, we wish you a good and beautiful summer.

When sacred buildings get on in years, the damage often shows up on the roof and windows. This was also the case with the church in Brünisried, which was in need of urgent renovation in the roof area. Also involved: HP Gasser AG from Lungern, Obwalden with special services in roof window element construction.

The task was clear: The roof of the church, which dates back to the 1960s and was in serious need of renovation, was in urgent need of repair. The roof renovation itself was carried out by Aebischer AG Bedachungen/Spenglerei from Plaffeien. In cooperation with the company’s roof window element construction division, the roof windows were also renewed. The special roof windows had to be restored to the same shape and appearance as they were in the original. At this point, the specialists of HP Gasser AG roof window element construction came into play.

It was demanded by the monument protection that simple roof window elements should not be installed here. The shape and appearance of the old roof windows were to be restored very closely to the original. In addition, it was important that the current Minergie requirements also had to be met. A task that suited the experts at HP Gasser AG perfectly. After all, the roof window element manufacturers have already shown their inimitably professional side with high attention to detail on several occasions, even in difficult projects.

Quality from Lungern proves itself

After the construction plans were available, the window manufacturers of HP Gasser AG set to work. True to size, the frames for the roof window elements were prepared and then the glazing was installed. An HPG oecoline vario® roof window element with ornamental glazing was used. The glazing presented a special challenge: the glass had to be patterned in accordance with the requirements for the protection of historical monuments. A special sandblasting process was used to incorporate the vertical white stripes into the glass in order to achieve the required optical glass subdivision.

Even with such a special task, the quality from Lungern has proven itself to the best. In the end, HP Gasser AG succeeded in installing a new roof window element on the roof of the church in Brünisried, which matches the appearance of the old windows from the 1960s and at the same time meets the current energy requirements. Challenge accepted, tasks fulfilled down to the last detail and, in the end, another contribution to a better quality of life and energy savings. Even in a renovation project that must meet the strict requirements of historic preservation.

Deutsch

Deutsch  English

English  Français

Français